Mike the Boilerman - Independent Gledhill Pulsacoil repair specialist in Hungerford, Berkshire

Call or text me on: 07866 766364

Mike the Boilerman - Independent Gledhill Pulsacoil repair specialist in Hungerford, Berkshire

Call or text me on: 07866 766364

The Pulsacoils:

Various:

The Pulsacoil 2000 was a major improvement over the preceding model the Pulsacoil III. The whole appliance was built inside a rectangular metal case with all the control components concealed inside, rather than being attached to the outside and vulnerable to physical damage as with the preceding Pulsacoil III. The design was simplified by disposing of the blender valve and flow switch allowing the sensor/PCB to do all the water temperature control, and the level switch in the header tank was also deleted, with failure from low water level being indicated simply by failure to send hot water to the taps!

How does the Pulsacoil 2000 work?

An immersion heater heats the water inside the thermal store. The thermistor (heat sensor) attached to the domestic hot water outlet from the plate heat exchanger detects a fall in temperature and tells the circuit board which runs the pump. The pump circulates stored hot water through the plate heat exchanger, heating it, and the circuit board turns it off again when the thermistor reports a temperature rise. This system is proportional as with the Pulsacoil III. The bigger the temperature fall seen by the thermistor, the faster the circuit board runs the pump. This way the designed flow temperature (of 52 degrees Celsius, I think) can be maintained at almost any flow rate when a hot tap is turned on.

Common problems:

The vast majority of Pulsacoil 2000 breakdowns to which I am called out fall into one of the following categories:

1) Tripping of the overheat protection thermostat.

On the early unmodified Pulsacoil 2000 the red 'Fault' light comes on and the unit fails to heat up until the front cover is removed and the manual 'overheat reset button' is pressed. A upgrade kit is available from Gledhill to cure this and most Pulsacoils will have had this kit fitted, which then sometimes leads to a different problem where the individual overheat thermostat in the lower heater trips. When this happens, the unit stops heating up overnight but the daytime boost heater still works. Re-setting the tripped thermostat is straightforward and described in my video here:

2) Depleted water in the thermal store.

The Pulsacoil 2000 is filled with water using a small header tank installed separately above the unit. This is not always permanently connected to the mains supply (usually when an overflow pipe to outside cannot be fitted), which means water lost from the thermal store through evaporation and/or leaks needs to be replaced manually. If the water level in the Pulsacoil 2000 falls too low, the pump simply does not have enough water to pump through the heat exchanger when a hot tap is turned on, and the unit will not deliver hot water.

The problem starts intermittently, and the unit runs noisily. The answer is to check the water level in the header tank and top it up to the waterline moulded into the wall of the tank

3) Water dripping onto the floor.

As the Pulsacoil 2000 model grows older, a problem is emerging where the copper tank inside leaks, and water oozes through the outer steel case near the bottom and drips slowly onto the floor. Water also emerges from where the pipe feeding the pump passes through the outer steel case at the bottom. This is never an emergency as the leak is always very slow, and people call me thinking a joint needs tightening or a seal replacing but sadly this isn't the case. The leak is a pin-hole in the copper tank inside could be anywhere on the tank. The leaking water percolates down to the base through the rigid foam insulation filling the space between the inner copper tank and the outer steel case, saturating it. Finding this leak is impossible as there is no access to the inner copper tank without stripping off the outer steel case and all the foam insulation. Technically feasible (just), but always cheaper to buy and fit a new unit. If your Pulsacoil is showing these symptoms but the leak is manageable, i.e. not making the floor wet enough to damage anything, there is perfectly feasible to just live with it. The water leaking out will mean the header tank on top needs topping up every few weeks as in 1) above, but there are no other consequences. If you have this problem, see Replacing a Pulsacoil.

4) DHW sensor failure.

The heat sensors (there are actually two) can become unreliable with age. This usually presents as unpredictable hot water performance or unstable hot water temperature. The thermal store will be hot, but the pump will not run fast enough (or at all) when the hot tap is open. The circuit board may be reporting sensor failure via it's red LED. One flash per second indicates flow thermistor failure, seven flashes per second indicates the pumped return thermistor has failed. Two flashes per second means the circuit board thinks both thermistors are good, but this is not always true in my experience, and changing both apparently good thermistors on a unit behaving inconsistently can often cure the problem.

5) Circuit board failure.

No flashes on the circuit board LED means circuit board failure, usually. If there is 240v across the live and neutral terminals on the board yet no LED flashing, then board failure is virtually certain.

6) Immersion heater element failure.

The unit fails to heat up. Easily diagnosed by measuring the resistance of the heater element. A good element will measure 18 Ohms approximately.

7) Immersion heater leaking.

Older 'Skel' brand immersion heaters (fitted as original equipment) seem to suffer from leaks in the thermostat sensor pocket. On many occasions I've seen water emerging from the copper tube in which the thermostat sensor is housed. This is clearly dangerous as it introduces water into the electrical connection box on the heater element head, and it often results in thermostat failure. The only repair is to replace the whole immersion heater and thermostat.

8) External Economy Seven time clock failure.

PulsaCoils are usually connected to an Economy Seven tariff electricity supply. When there is no separate off-peak power supply to the unit an Economy Seven timer will have been fitted. These seem to fail after a few years and no longer deliver power to the immersion heaters, even when the indictor lights on the timer say power is being delivered!. Although it's a straightforward matter to replace these timers, finding an electrical merchant who keeps them in stock can be very difficult. I keep them in stock myself as a result.

9) Water scale-contaminated plate heat exchanger.

The plate heat exchanger is prone in some areas to water scaling. This presents as maximum water temperature becoming progressively lower, and in the final stages of scaling, the flow rate from the taps reducing too. The fix is to either fit a new plate heat exchanger, or to descale the existing heat exchanger using conventional descaling techniques.

10) Leak inside the plate heat exchanger.

The plate heat exchanger is prone to damage from excessive mains water pressure, so Gledhill specify that a pressure regulator or limiter if there is any risk of the mains water pressure ever rising above 3.0 bar. If damage from high pressure occurs, the result is water leaking internally from the mains water side of the heat exchanger into the thermal store water side. This results in the ‘grey box’ header tank on top of the appliance overflowing, usually very slowly. The unit continues to work but the headrer tank needs manually bailing out every few hours until the heat exchanger is replaced, as they are not fitted with an overflow pipe.

11) Pump failure

Pump failure is actually quite unusual on a Pulsacoil 2000 but I commonly hear of pump replacement when an inexperienced technician attending a broken Pulsacoil 2000 and notices the pump is not running. He or she tends to jump to the conclusion the pump must be faulty and needs replacing when the actual fault is the PCB is not delivering any voltage to the pump. (Caused by sensor failure 4, above.)

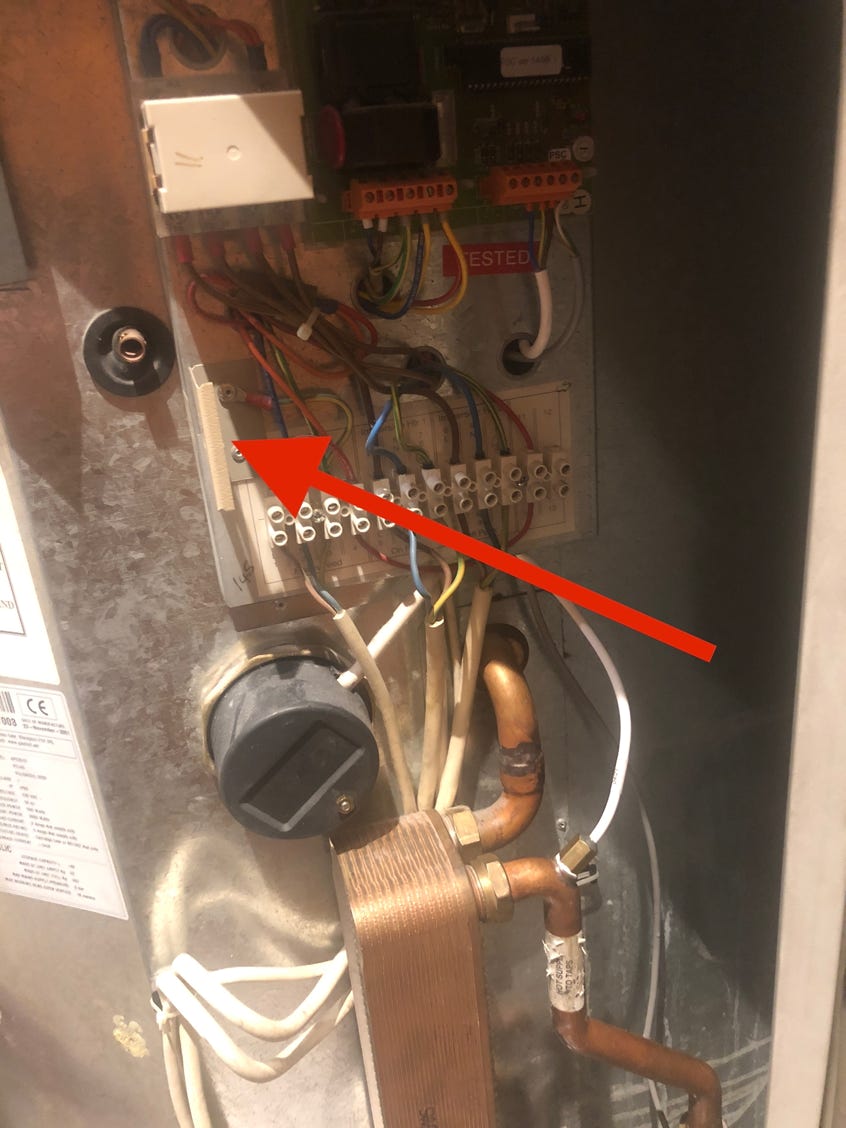

12) And finally, tripping of the originally installed overheat thermostat.

The originally installed overheat thermostat will have been replaced on 95% of Pulsacoil 2000 boilers with the later version in my video above, but there are still a few out there with the original overheat thermostat fitted just below the control circuit board. When this original overheat protection thermostat trips, the red “Fault” light on the main user control panel on the front of the appliance lights up and nothing works. The front panel needs removing and the the button pressing in. I can’t find a photo of this button which needs pressing in when the front panel red light turns ON, the best I can do is post a photo showing where the button was fitted on a Pulsacoil that has had it removed! See below. The big red arrow points to the bracket which has the button fitted into it, if yours still has the old overheat thermostat. If yours looks like the photo and there is nothing there at the end of the arrow head, then yours has been upgraded and you can re-set it by following the video nearer the top of this page. But if yours has a button (sometimes under a black cap which unscrews) at the arrow head, press it in and your Pulsacoil may well start working again.

If you'd rather I came and fixed your Pulsacoil 2000, call or text me on my mobile, 07866 766364

A Pulsacoil 2000 installed near Guildford, just prior to replacement. Note the water marks on the floor where the internal store is leaking.

Location of the old-format overheat thermostat. (This photo just shows the bracket left behind, on an upgraded Pulsacoil)

Copyright Michael Bryant 2023

Site first published 2nd January 2007

Last maintained 18th October 2024

Gas Safe Register 197499, CIPHE registration number 56207

This website makes use of cookies. Please see our privacy policy for details.

OK